Looking for alternatives for conventional hotends and their problems with heat barrier we decided to try ceramic one. After many trials concluion is that ceramic hotend has to high thermal conductivity. Active cooling is needed. Power consumption by ceramic part is about 20W !

Test results below:

Tests output:

Constant parameters:

- Environment temperature : 21C

- Resistor 5.6 Ohm, 5x16 mm

Day I:

Conditions: Not isolated Hotend at 230 C and bare Ceramic.

Result: Heating time: 11 min, After 30 minut cold end 110C.

Day II:

Conditions: Not isolated Hotend at 230 C and Ceramic barrier with little alloy radiator. Result: Heating time: 12.30 min, After 30 minut cold end 102C.

Day III:

Conditions: Isolated Hotend by silicone coating at 230 C and bare Ceramic.

Result: Heating time: 22 min ??!!, After 30 minut cold end 110C.

Day IV:

Constant parameters:

- Environment temperature : 21C

- Resistor 4.7 Ohm, 5x16 mm

Test I:

Conditions: Isolated Hotend by

silicone coating at 230 C and bare Ceramic, No cooling.

Result: Heating time: 7 min , After 30 minut cold end 110C.

Test II:

Conditions: Isolated Hotend by

silicone coating at 230 C and bare Ceramic,

Active cooling, by direct air flow..

Result: Heating time: 12 min , After 30 minut cold end 95C.

Test III:

Conditions: Isolated Hotend by

silicone coating at 230 C and bare Ceramic,

Passive cooling, by little radiator.

Result: Heating time: 8 min , After 30 minut cold end 95C.

Test IV:

Conditions: Isolated Hotend by

fire resistant concrete coating at 230 C and bare Ceramic, No cooling.

Result: Heating time: 5.min, 30 sec After 30 minut cold end 95C.

Test V:

Conditions: Isolated Hotend by

fire resistant concrete coating at 230 C and bare Ceramic,

Active cooling, by direct air flow. Result: Heating time: 7.min, 30 sec After 30 minut cold end 45C.

Test VI:

Conditions: Isolated Hotend by

fire resistant concrete coating at 230 C and bare Ceramic,

Pasive cooling with alloy radiator . Result: Heating time: 6.min, After 30 minut cold end 90C.

Test VII:

Conditions: Isolated Hotend by

fire resistant graphit tape coating at 230 C and bare Ceramic,

Active cooling with alloy radiator . Result: Heating time: 5.min, 30 sec., After 30 minut cold end 55C.

Test VIII:

Conditions: Isolated Hotend by

fire resistant graphit tape coating at 230 C and bare Ceramic,

Pasive cooling with alloy radiator . Result: Heating time: 5.min, 0 sec., After 30 minut cold end 90C.

Day V:

Constant parameters:

- Environment temperature : 21C

- Resistor 3.3 Ohm, 5x16 mm

Test I:

Conditions: Isolated Hotend by silicone coating at 230 C and bare Ceramic,

Passive cooling, by little radiator.

Result: Heating time: 3.25 min , After 4 minut col end 55C, after 30 minut cold end 100C.

Day VI:

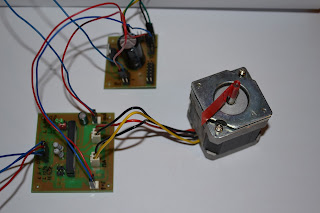

After offline tests, first ceramic hotend prototype ready for deployment:

Additional photos: